LEARN

Working with local industry waste & natural raw materials

-The Process

There are several stages involved in the making of Lulu’s unique glass recipes and collections.

Depending on whether it is a client, commission or personal project, the first step is to determine which recipe and material/s she is interested in investigating, taking inspiration from ancient glass texts and historical records. This is often based on a soda-lime glass, working with a former, a flux, and a stabiliser.

-Stage One

Location

Lulu is interested in developing regional glass recipes, so sourcing as many of the ingredients from one particular area or region. The final glass can then be reflective of the local landscape, as the chemical composition of the chosen materials will determine how it looks & behaves. This also the reduces the need for global transportation of finite raw resources typically used in glass making.

For example, her first collection ‘Thames Glass’, was made using materials sourced in and around the River Thames such as local river sand, waste wood ashes and waste mussel shells. The glass was a distinct bluey-green colour which came from the process & raw materials used - resembling the idea of water.

-Stage Two

Cleaning, Cooking, Crushing

Once the materials have been sourced, the next stage is processing. This can include cleaning, drying, ashing, and crushing (depending on the the material type). The majority need to be fully dried out, often done using a dehydrator or natural sunlight in the right conditions. The materials are then sieved to get a fine powder in preparation for the batch and to help with the final melt.

-Stage Three

Chemical Analysis, Batch Formulation

Lulu has recently started to work with experts from the Glass & Ceramic Research Centre at Sheffield/Hallam University. Together they are able to carry out material analysis, small batch testing inc. colouration & viscosity, batch formulation and strength/durability tests.

This partnership explores bridging the gap between the scientific / technological / artistic and social aspects of glassmaking, as well as thinking about what is possible in terms of materiality, and opportunities for larger scale production runs.

After weeks of testing, once the final recipe is formulated, Lulu can then proceed to make the final batch ready for melting. She has worked with batch sizes ranging from 15kg - 90kg.

-Stage Four

Glass Blowing

The batch is then taken to the hot shop where it is added slowly to a furnace pot. This will help with the homogeneity of the melt and to achieve a workable glass. The melt time and temperature of furnace is dependable on several factors, including the recipe itself, size of overall batch, type of furnace, efficiency etc. The glass is then blown and shaped into the desired shapes working with skilled glassblowers, and then placed into the kiln to anneal.

PREVIOUS COLLECTIONS

-

Pearl Green Collection

This collection includes some of the first hand-blown Thames Glass pieces ever made. The difference in the colours comes from working with different sand sources. The designs are based on ancient drinking vessels and jugs.

All pieces were made at The Glass Hub using the nano melt furnace, in collaboration with glass blowers KT Rothe, Sacha Delabre and Rosie Power. -

Blue Purple Collection

The purple glass has had manganese added to create the rich violet colour, something which was once added to ancient glass recipes to act as both a colorant and a decolorant.

The blue colour is formed through a unique oxidising technique. These two glass recipes were melted in separate batches, hence the two different colours and collections.

-

Carafe & Tumbler Collection

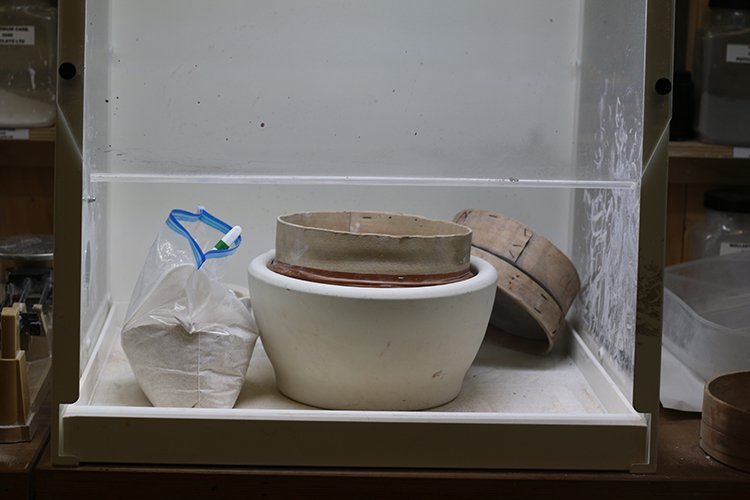

The most recent collection of Thames Glass pieces. Made in collaboration with Here Design and working with silica/plaster moulds to blow the pieces.

These were the first-ever prototypes made of the Thames Glass carafe and tumbler, with the aim of the collection to promote drinking tap water rather than buying plastic bottles.

“There are many ways we can help prevent the spread of non-native species, which left unchecked can have a significant and often destructive impact. Adopting the right biosecurity measures is essential to protect our local environments and, in this case, has the added benefit of using the quagga mussels in the creation of stunning glassware, making this project hugely exciting in the field of sustainability.”

— Rebecca Elliott, Biodiversity Manager,

Thames Water